VALVES AND ACTUATORS

36

valves sizing

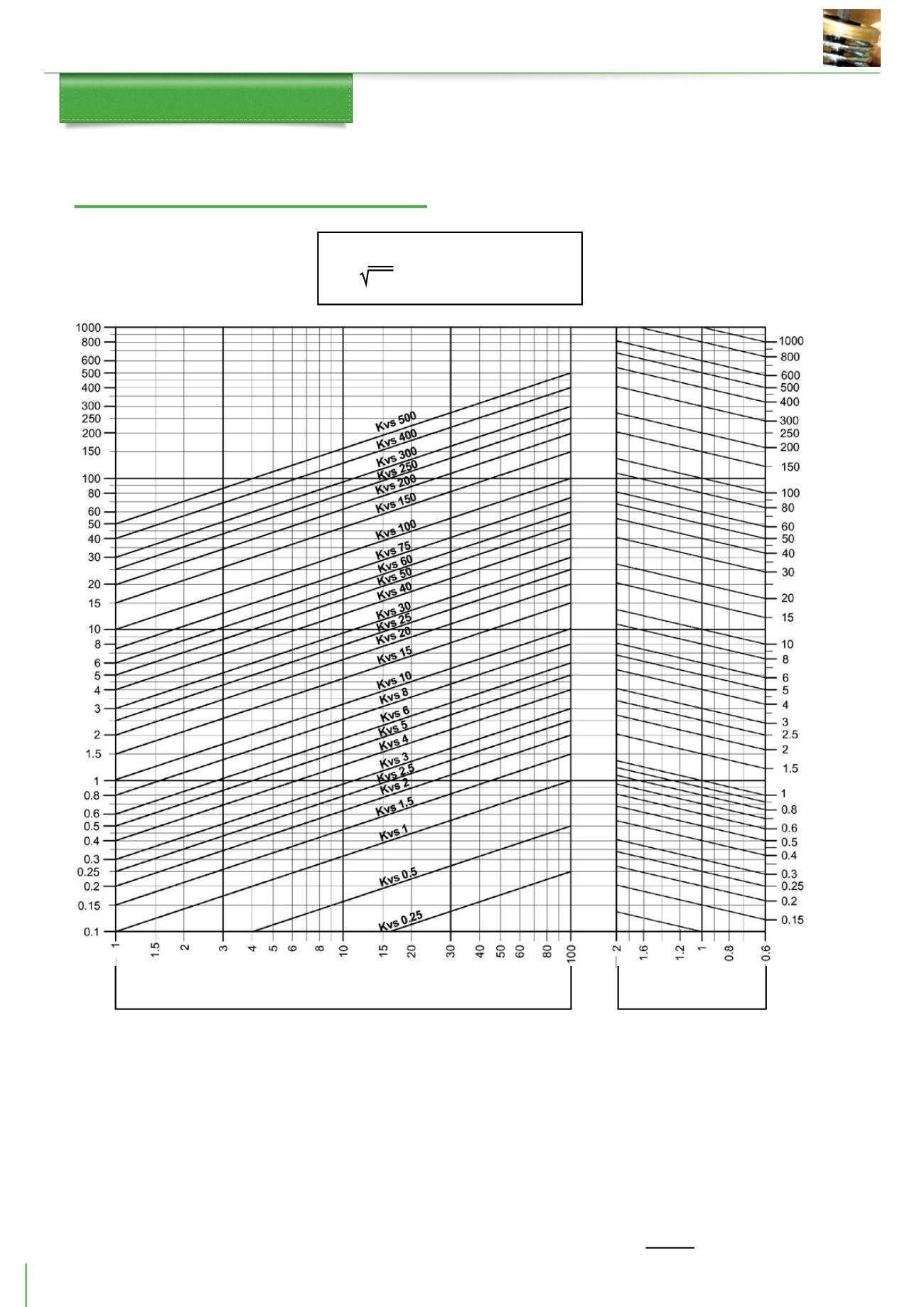

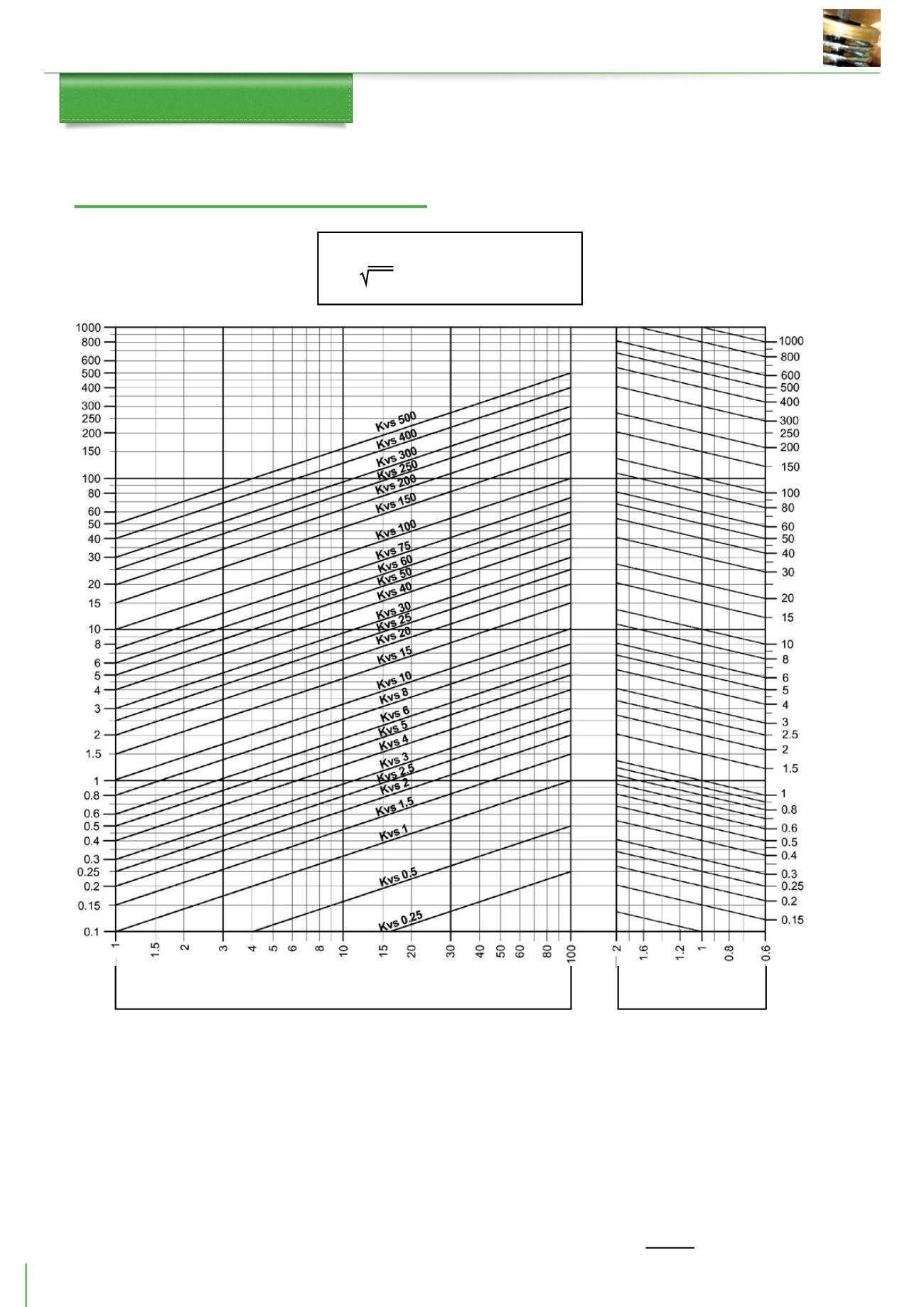

Valve Sizing Diagram for Fluids

Kvs = Q10

D

pv

Q = flow rate in m

3

/h

D

pv = pressure drop in kPa

Water flow rate in m

2

/h

Flow rate in m

2

/h

Pressure drop kPa

(100 kPa = 1 bar = ~ 10 m H

2

O)

Liquids with volume dif-

ferent from 1kg/dm

3

NOTA: the recommended valve pressure drop must be at least equal

to the load.

Example for fluids with relative density1 kg/dm

3

(water)

In order to size a control valve with:

FLOW RATE: 7.5 m

3

/h of water

PRESSURE DROP: 55 kPa

Use the diagram as follows:

- Identify the crossing point between the line starting from the flow

rate value (7.5 m

3

/h) and from the pressure drop value (55 kPa).

This point corresponds to the required flow coefficient,i.e.Kvs 10.There-

fore, the control valve must have Kvs 10.

Example for liquids having relative density different from 1 kg/dm

3

In order to size a control valve with:

FLOW RATE : 150 m

3

/h having (0.9 kg/dm

3

) relative density

PRESSURE DROP: 80kPa

Use the diagram as follows:

Identify the crossing point (right side of the diagram) between the line

starting from the relative density value (0.9 kg/dm

3

) and the inclined

line starting from the flow rate value (150 m

3

/h).

Identify the crossing point between the line starting from the crossing

point above and the other from the pressure drop value (80 kPa).

This point corresponds to the required flow coefficient. Therefore, the

control valve must have approximately kvs 160.

Example with diathermic oil.

It could be convenient to size the valve on diathermic oil using the wa-

ter diagram.To do this, it is necessary to apply the following conversion

formula, which takes into account the mass and the “average” specific

heat of diathermic oil:

Q = K calories in m

3

/h = water

D

t 500